Why Plastic Injection Molding Is Necessary for Accuracy and Longevity

Why Plastic Injection Molding Is Necessary for Accuracy and Longevity

Blog Article

Recognizing the Essentials of Plastic Injection Molding Processes

Plastic shot molding offers as a foundation of contemporary manufacturing, providing a systematic strategy to generating complicated elements with precision. Checking out these crucial elements could expose how even minor modifications can lead to considerable enhancements in manufacturing end results, raising questions concerning the capacity for development in this established procedure.

What Is Plastic Injection Molding?

Plastic injection molding is an extensively used production process that changes thermosetting and polycarbonate materials right into precise and complicated forms. This method is preferred for its ability to create high quantities of identical components with extraordinary precision, making it a vital method in different sectors, including vehicle, consumer goods, and clinical devices.

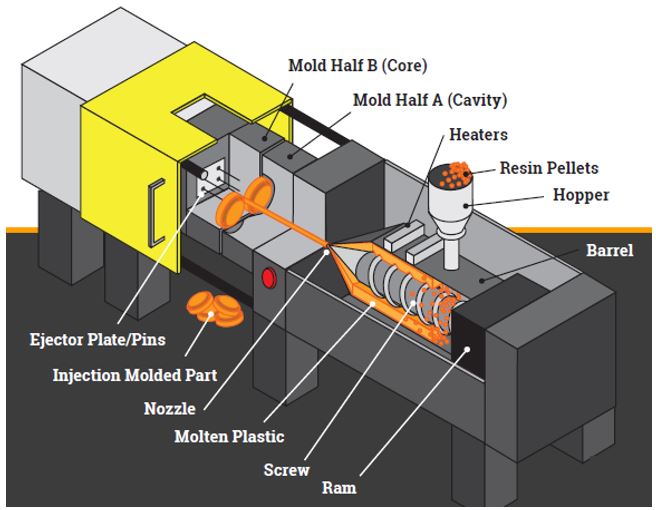

The process includes thawing the chosen plastic material and infusing it right into a mold under high pressure. The mold, made to the specifications of the preferred component, permits the liquified plastic to form as it solidifies and cools down. As soon as the product has actually hardened, the mold and mildew is opened, and the completed part is expelled.

Plastic shot molding supplies several advantages, including minimized waste, uniformity in manufacturing, and the capability to incorporate elaborate styles that might be testing with various other making approaches. Additionally, it supports a broad range of materials, each offering distinct residential or commercial properties that can be customized for certain applications. As industries remain to introduce, plastic shot molding continues to be at the center, enabling the development of advanced products that fulfill advancing customer needs.

The Shot Molding Process

The injection molding process is a sophisticated technique that entails numerous key stages to generate high-quality plastic components. Initially, plastic pellets are fed right into a warmed barrel where they are merged a viscous liquid. This molten plastic is after that infused under high pressure into a precision-engineered mold, which forms the product into the desired form.

As soon as the mold is filled, the plastic is allowed to cool down and strengthen, taking the form of the mold cavity. Air conditioning time is crucial, as it affects the cycle time and the last buildings of the shaped component. After adequate cooling, the mold and mildew opens, and the finished component is expelled using ejector pins.

Products Made Use Of in Injection Molding

Various materials can be utilized in the injection molding process, each offering unique residential properties that provide to details applications. One of the most commonly used products consist of thermoplastics, thermosetting plastics, and elastomers.

Thermosetting plastics, like epoxy and phenolic materials, undergo a chemical adjustment during the treating procedure, resulting in an inflexible, inflexible structure. These products are ideal for applications needing high warmth resistance and structural stability, often utilized in automobile components and electrical insulators.

Elastomers, including silicone and rubber-based materials, give adaptability and durability. Their distinct buildings make them suitable for applications that demand flexibility, such as gaskets and seals.

Additionally, specialty materials like bio-based plastics and composites are getting grip for their ecological advantages and enhanced performance qualities, expanding the range of shot molding applications in directory different sectors. Recognizing the residential or commercial properties of these products is crucial for selecting the suitable type for particular jobs.

Benefits of Injection Molding

Injection molding stands apart as a highly efficient manufacturing procedure that uses many benefits for creating complicated get rid of precision. One of one of the most substantial advantages is the capability to produce elaborate designs that would certainly be impossible or challenging to achieve with various other techniques (Plastic Injection Molding). The process permits detailed attributes and limited tolerances, ensuring high-grade elements

In addition, shot molding is known for its fast manufacturing abilities, making it a suitable option for high-volume manufacturing. As soon as the mold is produced, components can be generated rapidly, decreasing lead times and increasing total productivity. This performance not only reduces production prices but also offers an one-upmanship in the market.

The flexibility of materials used in injection molding further boosts its appeal. A wide variety of thermoplastics and thermosetting polymers can be used, allowing producers to pick materials that finest satisfy their details needs, consisting of warm, toughness, and flexibility resistance.

Furthermore, the process reduces waste, as excess material can usually be recycled and reused. This sustainability facet adds to a minimized ecological influence, making injection molding an accountable manufacturing selection. Generally, the benefits of injection molding make it a preferred method for several industries.

Variables Affecting Product Top Quality

While numerous factors can influence item top quality in shot molding, comprehending these elements is crucial for attaining optimum outcomes. Trick aspects consist of material option, processing parameters, and mold layout.

Material option plays a vital duty, as various polymers display distinct residential or commercial properties that impact flowability, strength, and thermal stability. Insufficient material selection can bring about problems such as warping or insufficient filling.

Processing parameters, including cycle, temperature, and stress time, have to be carefully regulated. Variations in these setups can lead to variances partially dimensions and surface coating. As an example, excessively heats may trigger destruction of the polymer, while inadequate pressure can cause short shots.

Mold style is equally crucial, as it identifies the circulation of the molten plastic and the cooling process. Poorly created mold and mildews might result in unequal air conditioning rates, resulting in recurring stresses and dimensional inaccuracies.

Verdict

In final thought, plastic injection molding offers as a vital manufacturing process that enables the effective production of top quality components. Mastery of the injection molding process, consisting of the understanding of products and the influence of various variables on product high quality, is crucial for accomplishing optimum outcomes. The advantages of this approach, such as cost-effectiveness and layout adaptability, further emphasize its relevance throughout several sectors, solidifying its standing as a favored option for high-volume manufacturing.

Plastic shot molding serves as a keystone of contemporary production, offering a methodical method to generating complex components with accuracy.Plastic shot molding offers numerous benefits, including decreased waste, uniformity in production, visit here and the ability to include intricate layouts that might be challenging with various other manufacturing techniques (Plastic Injection Molding). As markets proceed to introduce, plastic shot molding continues to be at the leading edge, making it possible for the advancement of advanced products that fulfill evolving consumer needs

The injection molding process is an advanced strategy that includes a number of vital stages to create premium plastic parts.In conclusion, plastic shot molding offers as an essential manufacturing procedure that enables the efficient manufacturing of top quality elements.

Report this page